Overview

Timeline: June 2024 – January 2025 | Lab: Accelerated Materials Laboratory for Sustainability

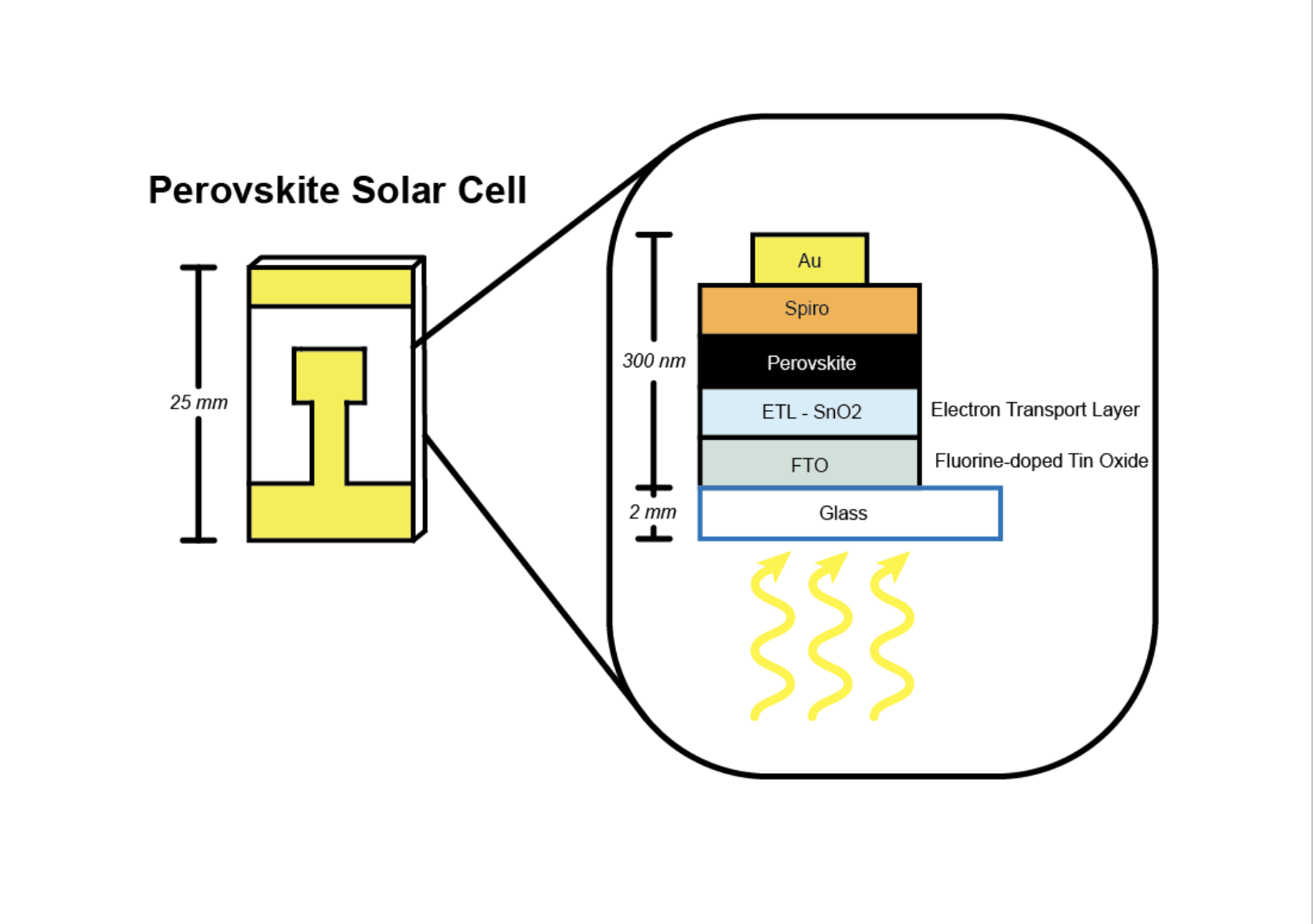

Perovskite solar cells represent a promising next-generation photovoltaic technology, offering high efficiency potential at low manufacturing costs. However, their performance and stability are highly sensitive to environmental conditions during fabrication, creating challenges for real-world deployment and manufacturing scalability.

This research focused on understanding and controlling the fabrication of perovskite solar cells across diverse environmental conditions. By developing precise environmental monitoring and control systems, we aimed to optimize the spin-coating deposition process and improve cell stability under varying humidity, temperature, and solvent vapor conditions.

My work centered on designing the fabrication processes, developing the environmental monitoring system, and analyzing the relationship between fabrication conditions and solar cell performance to enable more robust and scalable perovskite solar cell production.