Overview

Timeline: January 2024 – September 2024 | Lab: The Lienhard Research Group

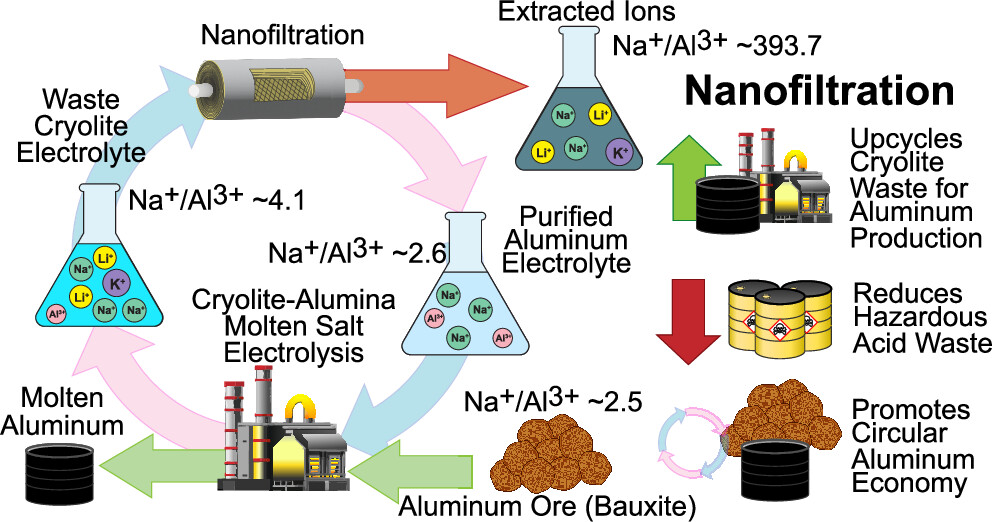

Aluminum refining produces cryolite-based electrolytes that gradually accumulate sodium, lithium, and potassium impurities, rendering them unusable and creating a persistent waste problem. Disposal of this spent cryolite contributes to fluoride and aluminum contamination in soil and water systems.

This research introduced a nanofiltration-based upcycling method that selectively removes monovalent impurities while retaining aluminum, enabling reuse of the purified electrolyte and significantly reducing environmental waste. A polyelectrolyte-coated NF membrane was developed to enhance charge-based selectivity, exploiting Donnan exclusion to favor sodium permeation and aluminum retention.